| Honeycomb Dehumidifier Details description |

|

| product name:Honeycomb Dehumidifier |

| release time:2020-05-16 13:57:59 |

| Numbering:HF-400 |

| Brand:HENGJU |

| Price:¥USD 6120 |

| simple description:Honeycomb dehumidifiers are mainly used to dry hygroscopic engineering plastics such as PET, PC, PLA, PA, TPU, TPE, HDPE, etc. |

| weight :330.00 |

| unit weight:KG |

| characteristic:For Plastic Material Drying |

| patent:Intelligent Drying System Control Software |

| manufacturer:HENGJU |

| Producing country:CHINA |

| Product alias:Honeycomb Wheel Dehumidifier |

|

| Honeycomb Dehumidifier Product introduction |

|

Honeycomb Dehumidifier parameter

| Model |

HF-400 |

| Drying Air Volume (m^3/hr) |

400 |

| Drying Blower Power (KW) |

5.5 |

| Regeration Blower(KW) |

0.75 |

| Regeration Heater(KW) |

7.2 |

| Cooling Nozzle(lnch) |

3/4" |

| Out/in Air Pipe Dia. (Inch) |

3 |

| Dimensions (LxWxH) CM |

126×70×170 |

| Net Weight (KG) |

330 |

Note: We reserve the right to change spencifications without prior notice.Honeycomb Wheel Dehumidifier |

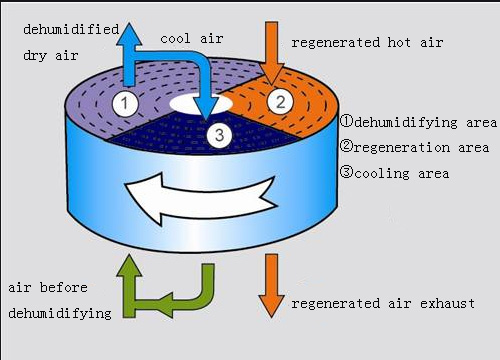

Honeycomb Dehumidifier Equipment principle

The core component of the honeycomb dehumidifier is a honeycomb rotor that rotates slowly. The partitions on both sides of the rotor made of highly sealed silicone rubber divide the entire surface into three sectors: the dehumidifying area, regeneration area and cooling area.

When the humid air enters the dehumidifying area of the rotor, the water vapor of the humid air is absorbed by the active silica gel of the rotor and enters the regeneration area, and then the dehumidified dry air is blowed to hopper dryer by blower.

There is plastic material with strong hygroscopicity inside the hopper. The dehumidified dry air absorbs the internal moisture of the plastic material. As the absorbed water increases, the rotor restores its ability to absorb moisture to complete the regeneration process.

Under the action of the drying blower, the dehumidified air is sent to the dehumidifier, and the dehumidification sector gradually becomes more saturated. Under the drive of the speed control motor, it slowly turns into the slow cooling zone, and the high temperature blown in reverse through the regeneration zone After the air adsorbs the moisture absorbed in the rotor, it enters the dehumidification area for dehumidification. The above-mentioned dehumidification and regeneration processes happen at the same time, the air is continuously dried, and the rotor is continuously regenerated, and the cycle is repeated, thus ensuring the continued stability of the dehumidifier.Honeycomb Wheel Dehumidifier |

Honeycomb Dehumidifier application

Honeycomb dehumidifiers are mainly used to dry hygroscopic engineering plastics such as PET, PC, PLA, PA, TPU, TPE, HDPE, etc.

Honeycomb Wheel Dehumidifier |

Honeycomb Dehumidifier Precautions

1,The dehumidifier should be cleaned frequently and kept clean.

2, When cleaning the machine, wipe gently with a damp cloth; avoid direct water splashing to avoid damage to electrical insulation.

3, If there are stickies on the surface of the machine, which can be washed with soapy water.

4, Avoid spraying with gasoline, petroleum spirit, solvents or spray insecticides to avoid peeling paint or discoloration.

5, Do not use thin rods or wires to dig inside the machine to avoid malfunction or danger.

6, Unplug the power cord to maintain the life of the machine when there is a power outage.

7, Put the machine stand up, not tilted or laid down, to avoid machine malfunction or abnormal noise. Product alias:Honeycomb Wheel Dehumidifier |

|

|